Oil

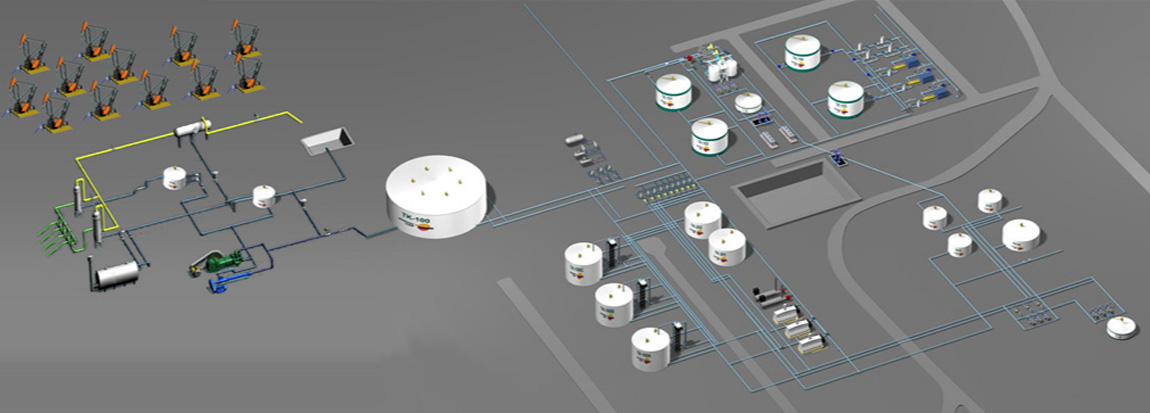

In this Market we can provide dosification solutions since production Wells, Batteries, API Pools, secondary recovery plants and tertiary and including crude oil dispatch through applications of special Chemicals for oil pipelines.

Gathering Stations

In this point we Find us in the gathering stations which are small plants who take the productions of a group of oil wells and it performs a second treatment of crude oil, it separates oil from gas and if is necessary the first separation from water which brings the petroleum. In these plants it injected similar chemicals to what we dose in the oil well to keep on treatment de product.

Automatic Dose Equipment: the dosing of emulsion breakers is very important, because this treatment ensures that the petroleum reaches the crude oil plant (last part of the treatment). Also it dosified hydrates inhibitors to avoid the freezing of gas pipelines. For this stage, we offer dosing systems who have two pumps mounted, one active and one in stand-by, with control systems of the series FL 250. These equipments have the advantage which monitors the right operation of the active pump. In case it fails, switches to the standby pump and sends an alert to the central control. Other accessories we can use, in compliment with the dosing systems, are retention valves which install on the injection points for assure the right dosing and avoid backpressures.

Oil Wells

Since which extracted the fluid and depending to its characteristics, are performed treatments with chemical products. These processes may be continuous or by Bach. We specialized in continuous systems, for these are used dosing pumps which operate 24hs the 365 days of year.

These pumps can dose various chemicals like: Corrosion Inhibitors, paraffin inhibitors, sulfur inhibitors, Flow improvers and others. In this application, we offer 3 options according the client necessity, all of them with a pump, a chemical tank, a filter for the chemical product and a calibration pot.

Oil Pipelines

In Occasions which be required increase the oil transport capacity, are used very specific chemicals called flow improvers. For these types of applications we use LY® Series Pumps, which respond to the API 675 Policy and assure heavy work 24hs a day and support pressures bigger than 1378 PSI. Is a Market in expansion, where Mirbla® is gaining positions; we are installing equipment in Argentina, Bolivia y Brazil.

Odorizer Equipment

The gas, who obtains from the Gathering Station, can be channeled for internal use (instruments drive or pneumatic dosing pumps) or for selling to gas distributors and industrial clients.

When it used for internal use is important odorize the gas, for security to detect losses inside of the plant. In this case we recommend equipment from the LU Series, which are designed for low flows and are cheaper.

Crude Oil Treatment Plant

EIn this Stage is the last chance of chemical treatment, because from here goes directly to selling. Here is very important that the chemical shall be injected correctly, because of this that the client requires more complete dosified systems. the oil samplers are applicable in the plant entry, to verified if the treatment in the previous plants are being optimum or require a reinforcement before arrive to plant tanks.

API Pools

It's very Common find API Pools in the Oil treatment plants, these fulfill the function of separate water from Oil, which can be stay in emulsion, in this case is used polymers in aqueous solution. The preparation equipment that we design, guarantee that the polymer is ready for application, ensuring a good treatment.

Secondary Recovery

To Increase oil production in an oilfield, is used the water reinjection, it pushes the oil to the extraction points and is obtained higher performance in the production. For this it used oil wells that decreased their production, transforming them in wells water injectors.